Precision Turning

Welcome to the realm of micro-engineering perfection – the world of Precision CNC Swiss Turning. Nestled within the heart of Turkey, Swiss Lathe stands as the vanguard of machining innovation, offering a symphony of precision and technology that transforms raw materials into intricate masterpieces with unparalleled accuracy. Crafted within our cutting-edge facilities, this method embodies the art of turning, redefining the boundaries of what is possible in the world of manufacturing.

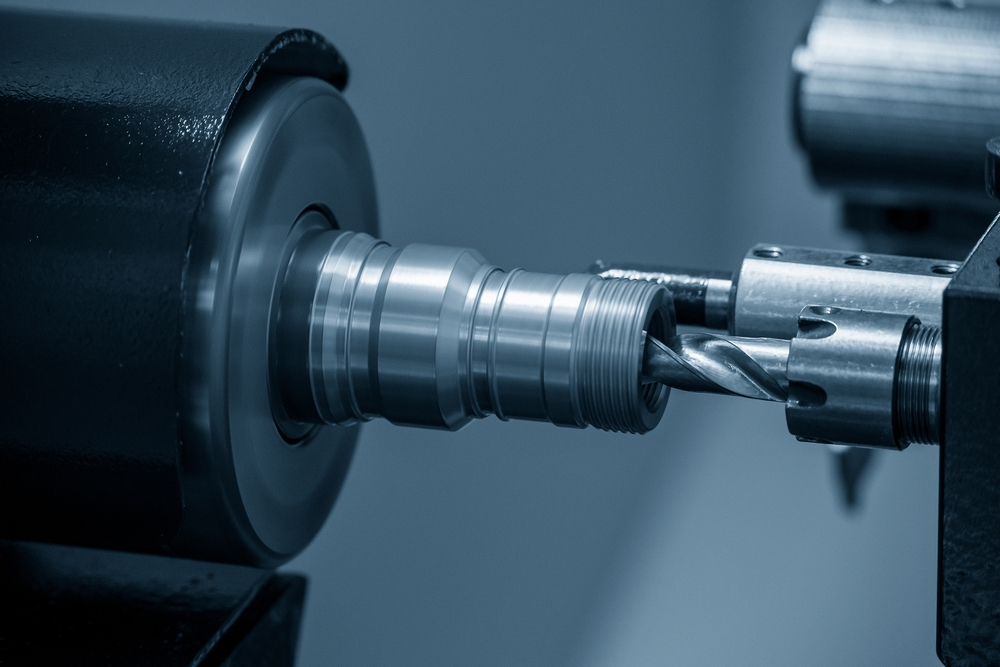

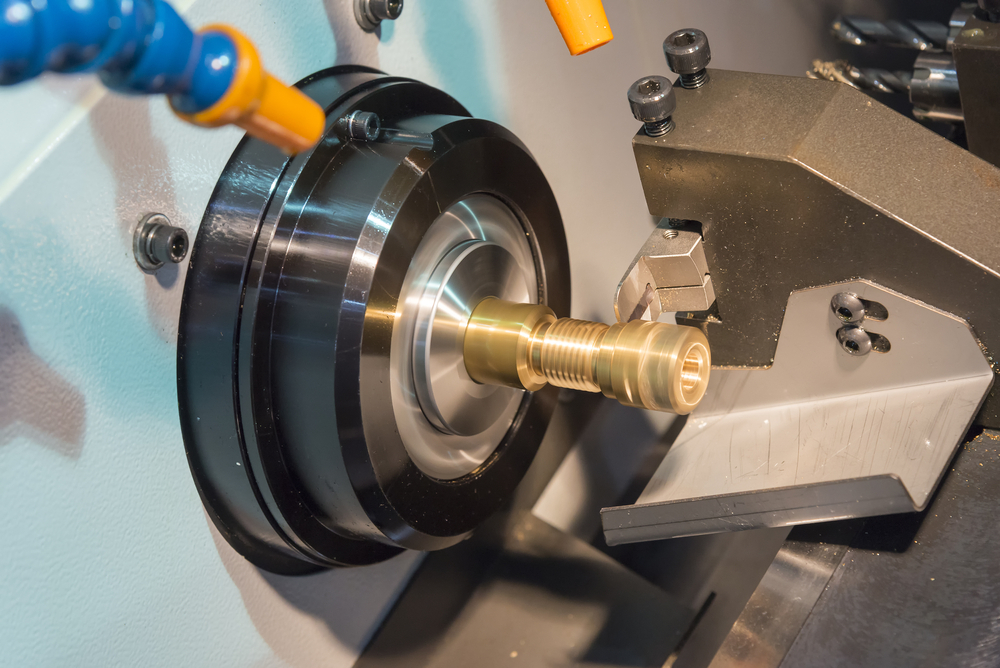

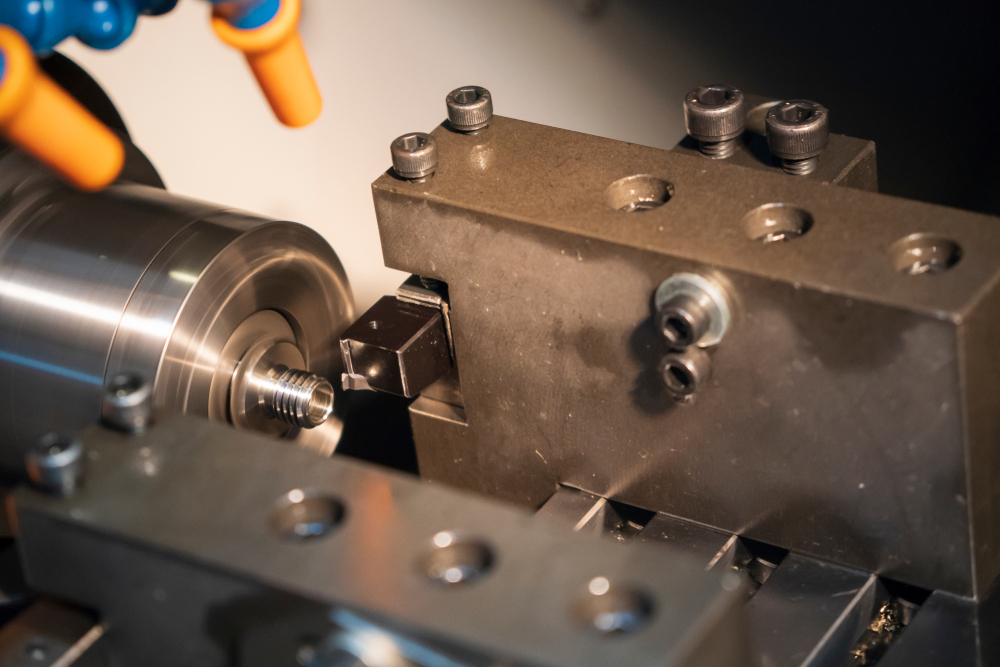

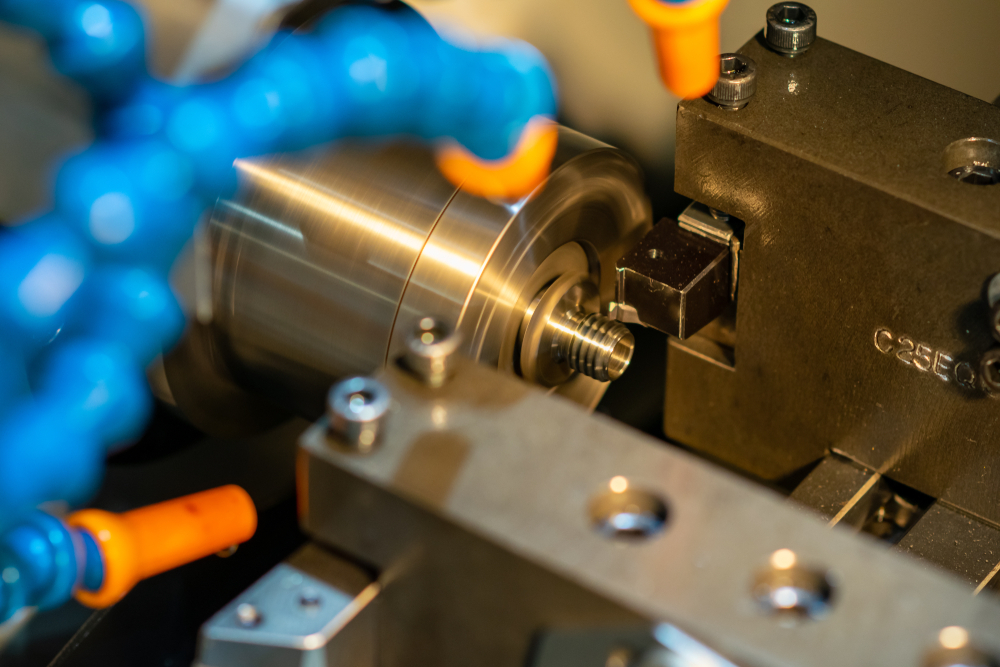

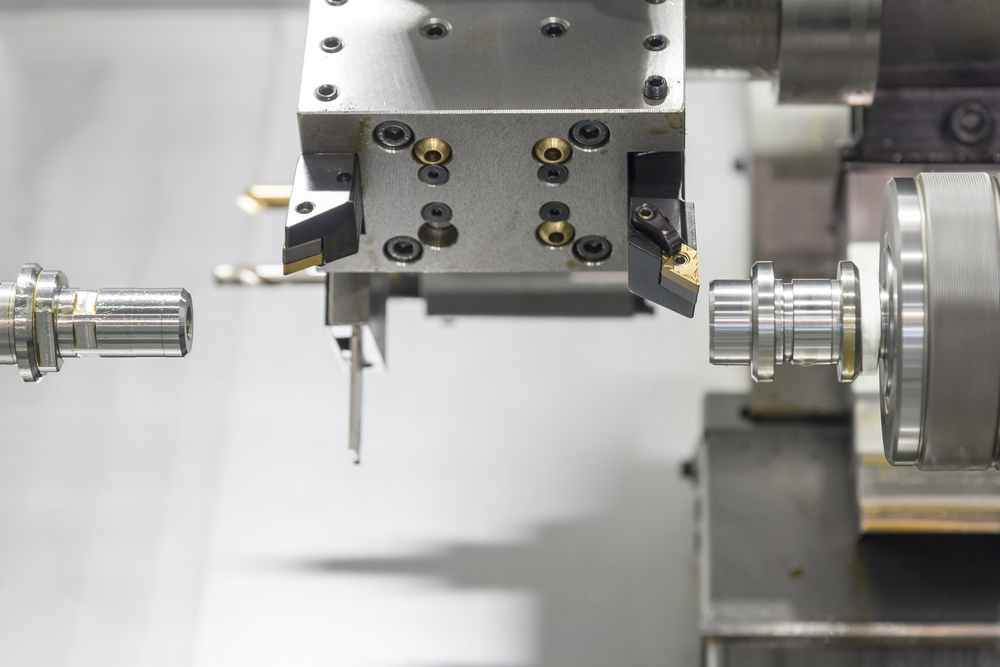

At the heart of Swiss-type machining lies a sliding headstock design, a marvel of engineering that cradles the workpiece within a rotating collet. This architecture provides exceptional support for slender workpieces, mitigating the risk of deflection and ensuring vibrations are held at bay. Guided by an intricate dance between sliding headstock and guide bushing, Swiss turning achieves the extraordinary – it crafts components of remarkable complexity and dimensionality, all while maintaining sub-millimeter tolerances that set the gold standard in precision.

Enabling this precision ballet is the automatic bar feeder, a seamless integration of mechanics that ensures a continuous supply of raw material. As a synchronized symphony of tools engages in simultaneous machining, intricate designs, and geometries are sculpted to perfection. The result: parts with tolerances often measured in hundredths of a millimeter, small yet critical components that grace industries ranging from medical devices to aerospace, from electronics to automotive.

Swiss Lathe, located in the vibrant landscape of Turkey, is not merely a machining company; it’s a beacon of quality and ingenuity. With the backdrop of Turkish craftsmanship, Precision CNC Swiss Turning is elevated to an art form, where micro-engineering excellence and visionary innovation come together, producing components that stand as testaments to the extraordinary heights precision machining can achieve. Join us on this journey as we craft the future, one precision piece at a time.

Key Features and Aspects of Precision CNC Swiss Turning:

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

- SWISS LATHE in TURKEY Sliding Headstock Design -- Guide Bushing -- Bar Feeder -- Simultaneous Machining -- Tight Tolerances -- Small-Diameter Workpieces -- Complex Geometries -- Superior Surface Finishes -- Automatic Feeder -- Production Speeds -- Machinable Dimensions -- Material Versatility --

Sliding Headstock Design:

Swiss-type machines feature a sliding headstock design where the workpiece is held by a rotating collet. This design provides enhanced support for long, slender workpieces, minimizing deflection and vibration during machining.

Guide Bushing:

A guide bushing is employed to support and guide the workpiece as it’s machined. This is particularly advantageous for machining long parts, as it reduces the risk of deflection and enhances accuracy.

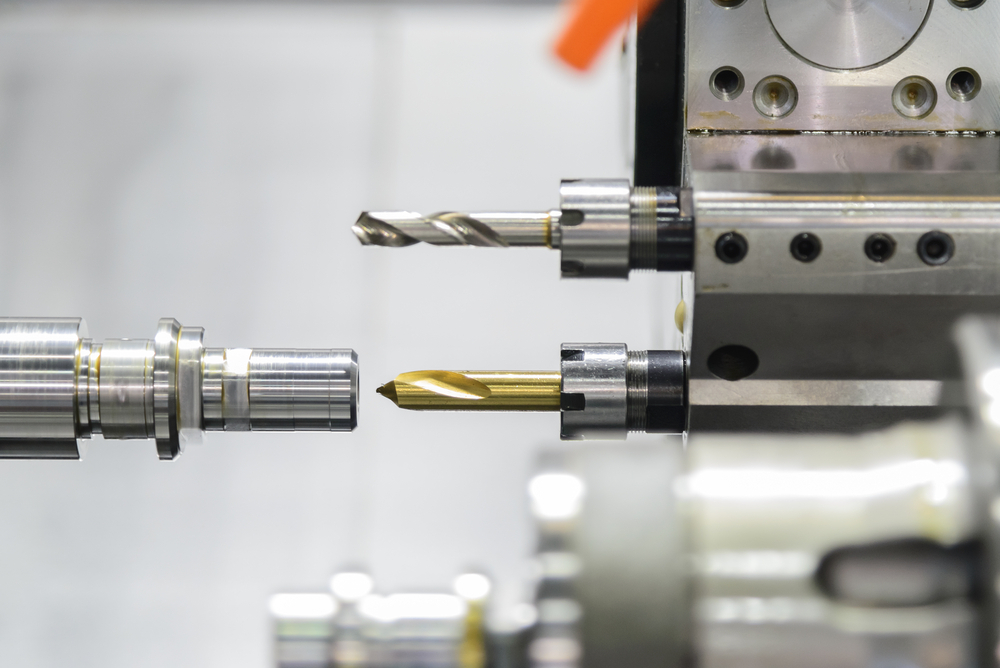

Bar Feeder:

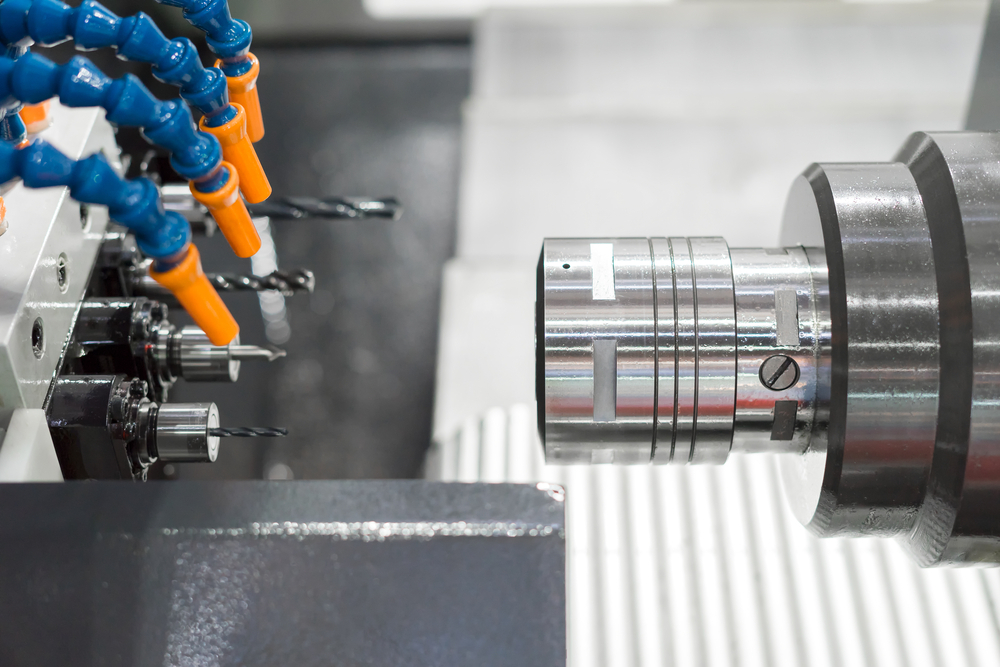

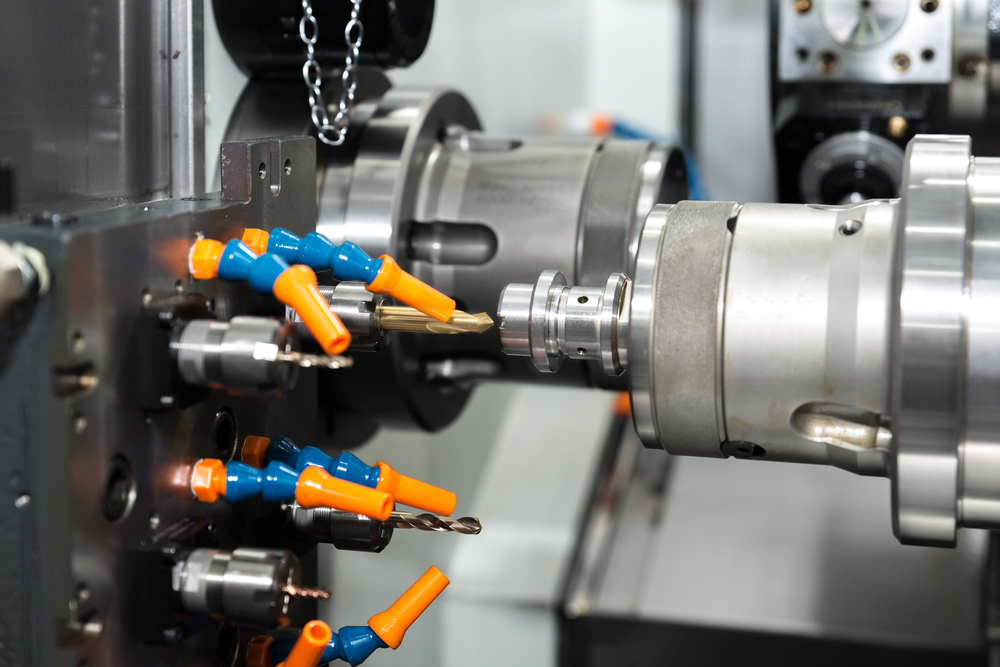

Swiss-type machines often incorporate an automatic bar feeder. This allows continuous feeding of long stock material through the guide bushing, enabling uninterrupted machining of multiple parts from a single bar.

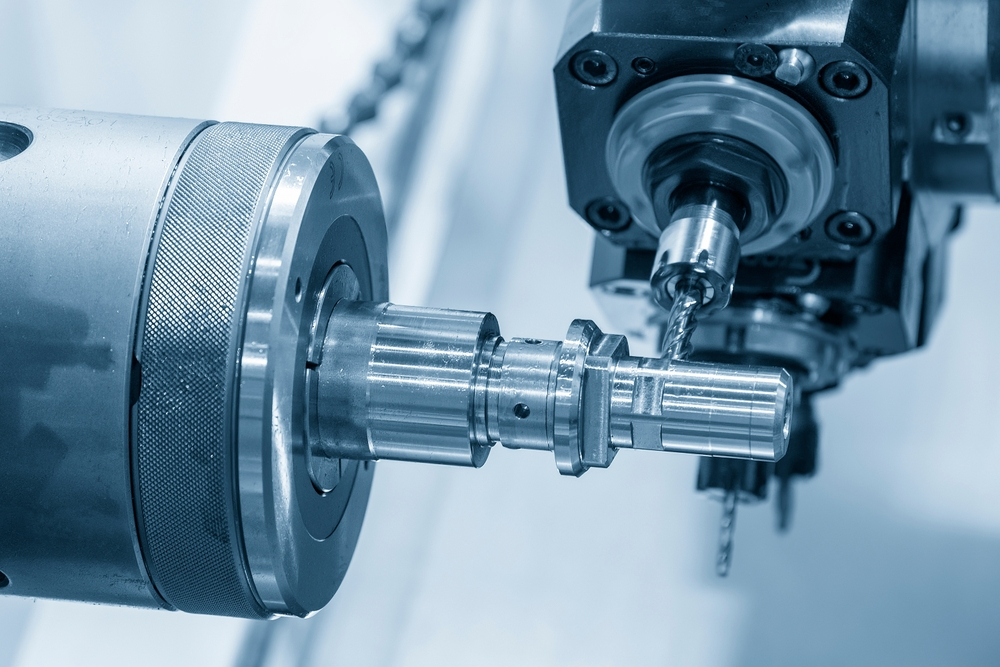

Simultaneous Machining:

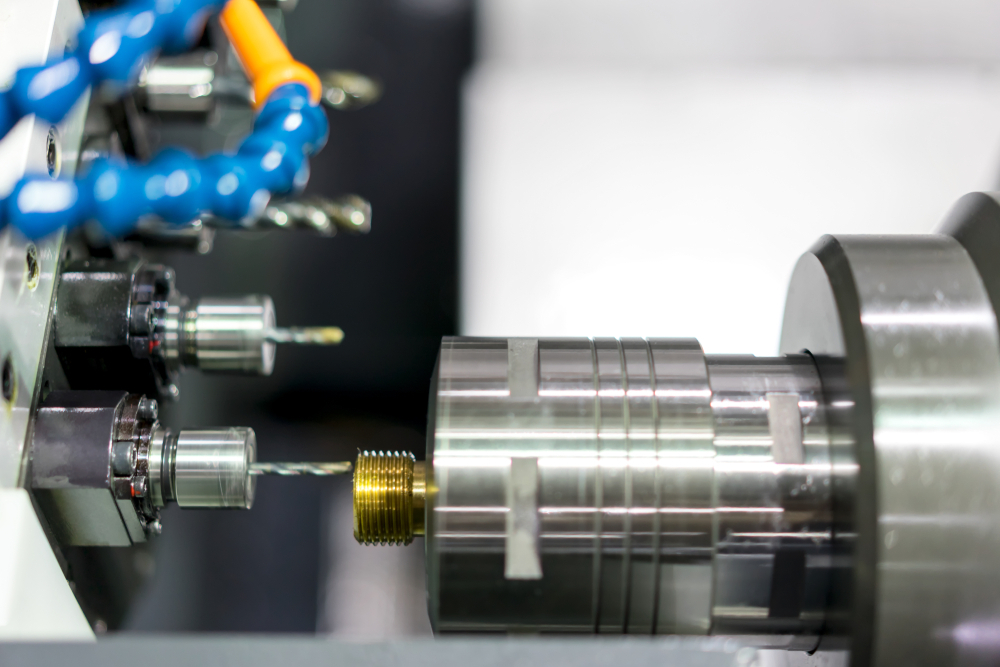

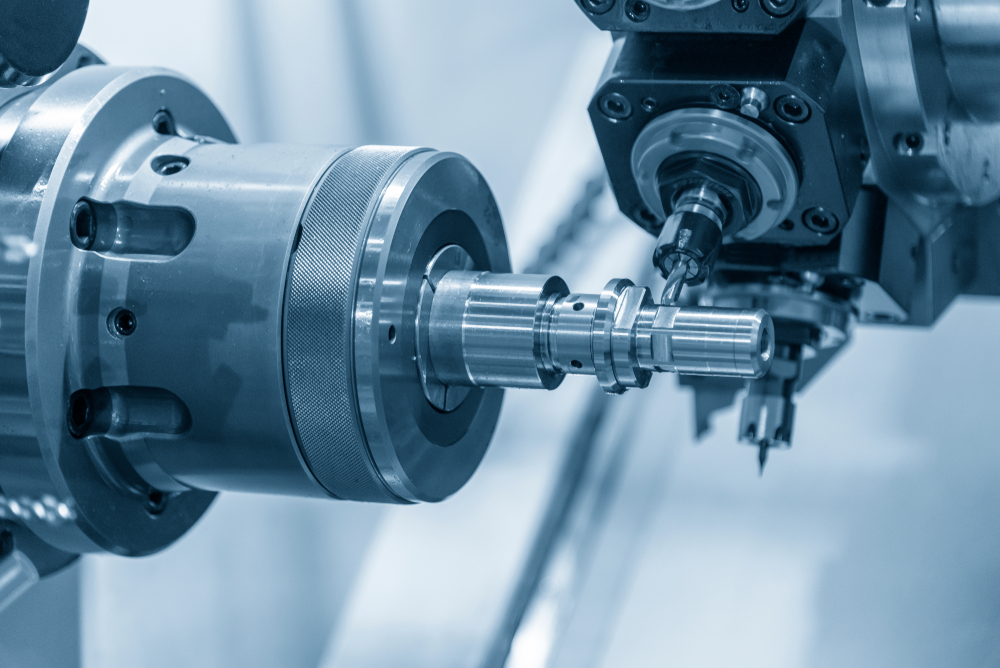

Swiss turning machines are capable of performing multiple operations simultaneously. Several cutting tools can work on the workpiece at once, reducing cycle times and boosting efficiency.

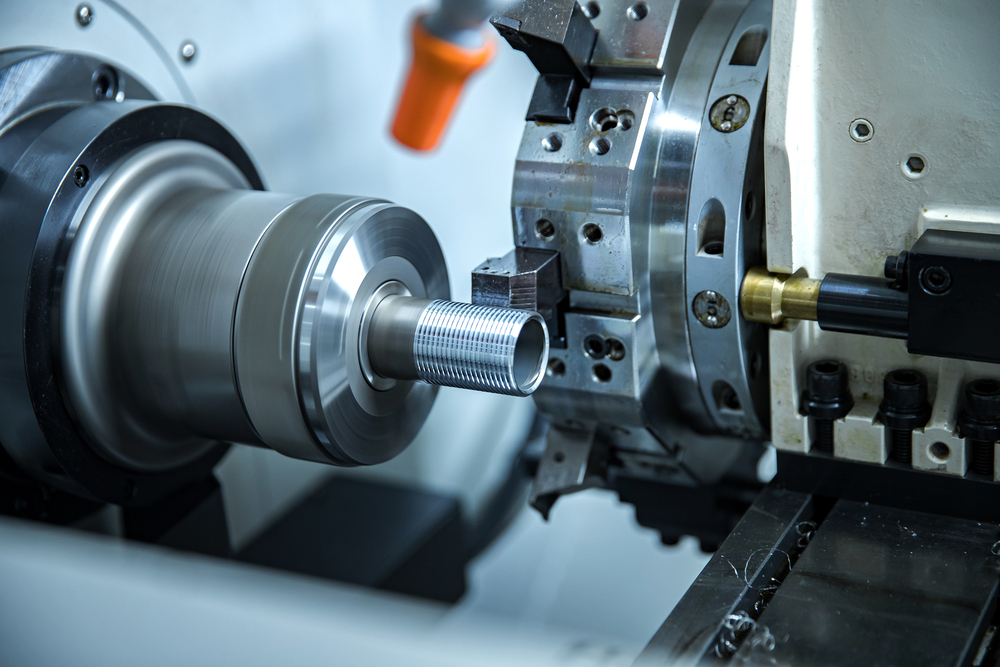

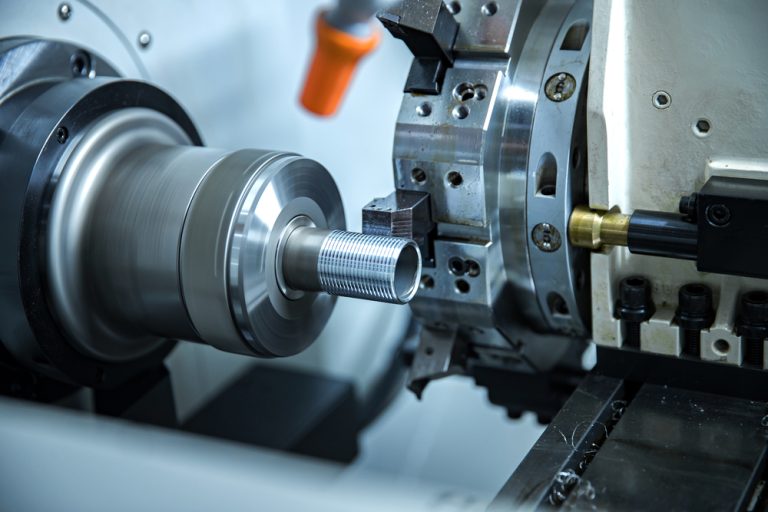

Tight Tolerances:

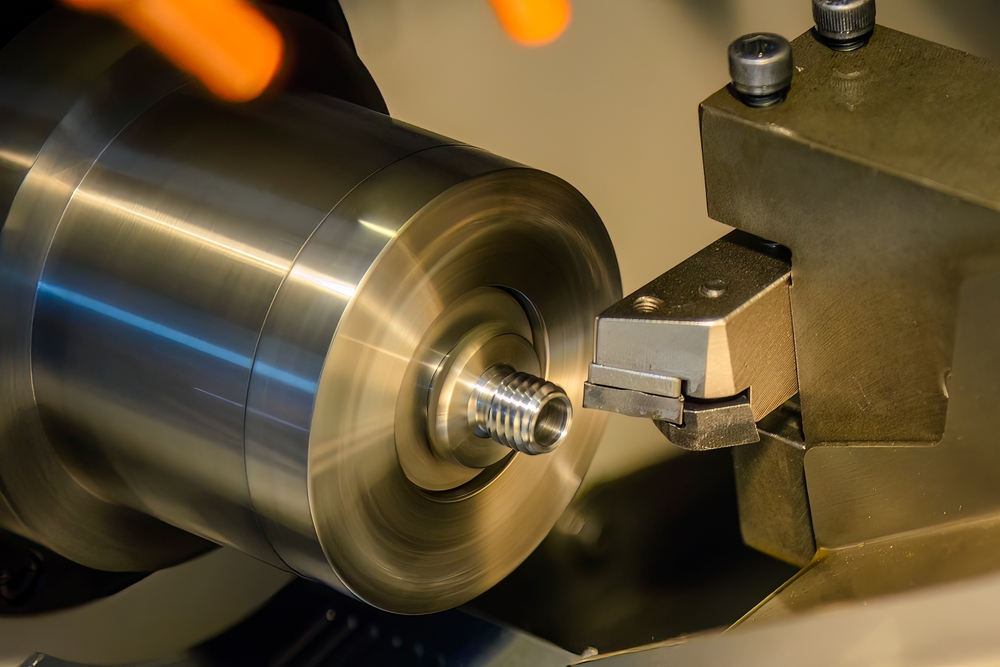

Swiss-type machining achieves extremely tight tolerances, often in the range of 0.01 to 0.05 millimeters. This precision makes it suitable for industries like medical devices, aerospace, and electronics.

Small-Diameter Workpieces:

Swiss turning specializes in machining small-diameter workpieces. Components with diameters as small as a few millimeters can be accurately machined.

Complex Geometries:

The combination of sliding headstock, guide bushing, and multi-axis capabilities allows Swiss turning machines to create intricate and complex part geometries in one setup.

Superior Surface Finishes:

Swiss-type machining produces excellent surface finishes, minimizing the need for additional finishing processes.

Automatic Feeder:

The automatic bar feeder enables the continuous supply of raw material, reducing manual intervention and increasing productivity.

Production Speeds:

Swiss-type machines operate at high speeds, contributing to efficient production. The simultaneous machining of multiple tools further accelerates the manufacturing process.

Machinable Dimensions:

While Swiss turning specializes in small-diameter components, the maximum length of machinable parts can vary based on the machine’s specifications.

Material Versatility:

Swiss turning accommodates various materials, including metals like stainless steel, aluminum, titanium, and exotic alloys, as well as plastics and engineering polymers.

Precision CNC Swiss turning finds applications in industries where precision, complexity, and efficiency are paramount. Components produced include fasteners, connectors, pins, screws, shafts, and more. The integration of advanced technology, skilled operators, and specialized machinery makes Swiss-type machining an ideal solution for producing high-precision components that meet the stringent demands of modern industries.

At Swiss Lathe, we fuse the expertise of our skilled artisans with state-of-the-art Swiss-type machines, magnifying the capabilities of Precision CNC Swiss Turning. Our sliding headstock design, where a workpiece is cradled by a rotating collet, offers unprecedented support for long, slender components. This design choice minimizes deflection and vibrations during machining, ensuring that our products meet even the most stringent tolerances.

With the aid of guide bushings, we amplify accuracy in the machining of long parts, delivering impeccable results that adhere to the highest precision standards. Our commitment to seamless production is further empowered by the integration of automatic bar feeders, enabling the uninterrupted supply of raw material. This paves the way for continuous and efficient machining, making us a leader in the production of multiple components from a single bar.

Swiss Lathe thrives on simultaneous machining, a technique that orchestrates the synergy of multiple cutting tools to sculpt intricate designs with unparalleled finesse. In this choreography of precision, Swiss turning machines craft components with tolerances often measured in hundredths of a millimeter – a testament to our dedication to excellence. Our production speeds, synchronized symphony of tools, and mastery of multi-axis capabilities further exemplify the prowess of our Swiss turning services.

Our journey through Precision CNC Swiss Turning uncovers the capacity to craft components with the utmost precision and finesse. From the aerospace industry’s complex geometries to the medical sector’s tight tolerances, Swiss Lathe’s versatility shines. Whether it’s fasteners, connectors, pins, screws, shafts, or more, Swiss Lathe’s capabilities cater to the unique demands of modern industries.

As a beacon of Turkish craftsmanship and innovation, Swiss Lathe epitomizes the transformation of raw materials into works of micro-engineering art. Join us on this journey, where precision meets passion, and cutting-edge technology converges with age-old artistry to shape the future, one impeccably machined component at a time.